Compacted homogeneous floor covering Wear-resistant grade:T grade of wear-resistant grade and improvement of wear resistance Environment - friendly plasticizer:a new generation of non phthalic plasticizers suitable for food plasticizer for chiIdren's toys and care products. Air quality:TVOC release is lower than European standard,and the optimal air quality is guaranteed

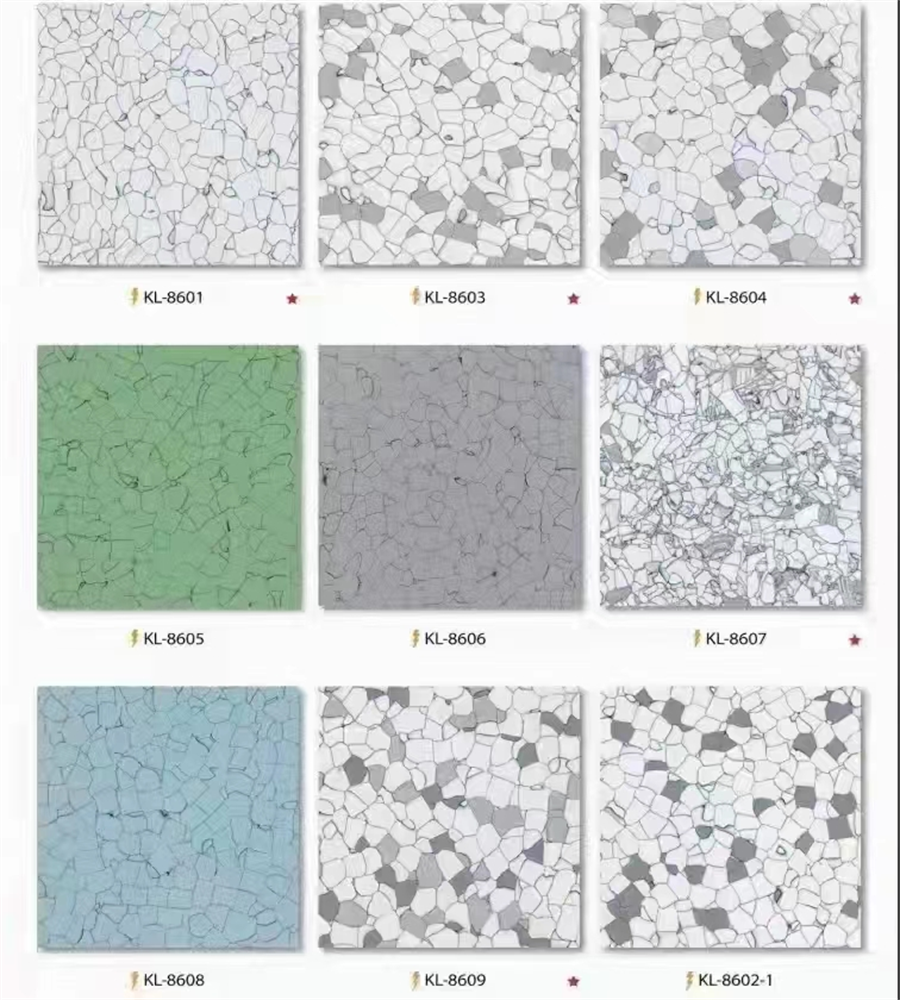

Compacted homogeneous floor covering Wear-resistant grade:T grade of wear-resistant grade and improvement of wear resistance Environment - friendly plasticizer:a new generation of non phthalic plasticizers suitable for food plasticizer for chiIdren's toys and care products. Air quality:TVOC release is lower than European standard,and the optimal air quality is guaranteed | Product Name | ESD Vinyl Floor |

| Thickness | 2-3mm |

| Size(mm) | 600 x 600/ 610 x 610/ 900 x 900 |

| Type | Conductive or Antistatic |

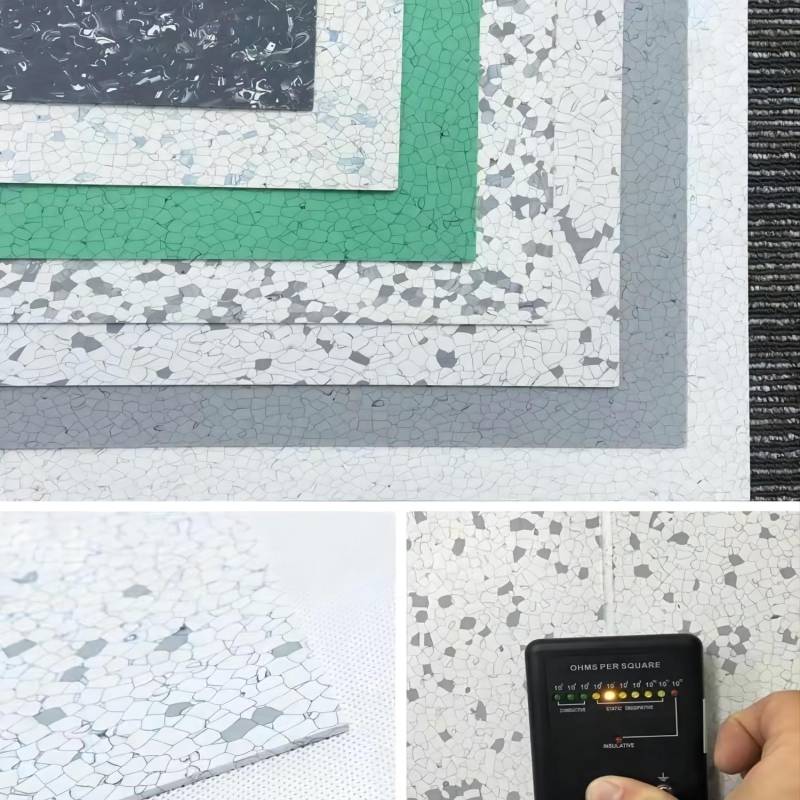

Conductive anti static Homogeneous vinyl floor can withstand heavy traffic and staining for a true low-maintenance floor perfect for health care and education environments,such as hospital,school,museum ,lab etc.

Conductive anti static Homogeneous vinyl floor can withstand heavy traffic and staining for a true low-maintenance floor perfect for health care and education environments,such as hospital,school,museum ,lab etc.

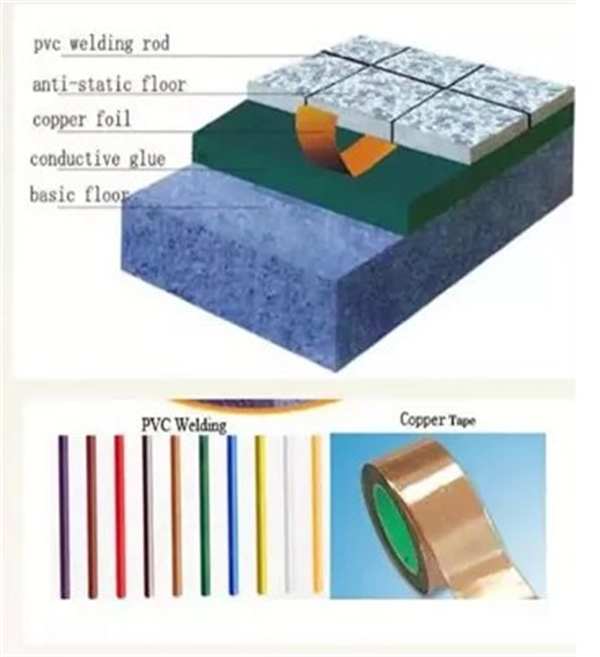

Installation

Conductive tile and Static-Dissipative tile should be installed on sub floors that are leveled,smooth and free of cracks. Residual humidity should be under 2.5% tested with the CM Dumb test.Tiles, adhesive and installalion site should reach a temperature of at least 18℃ and 24 hours before installation. And Paste the Tiles with qualified conductive glue below 10eh ohm for further details on installation methods.

| Item | Standard | Index |

| Size | SJ/T11236-2001 ASTM F536-98 | 600*600mm |

| 610*610mm | ||

| 900*900mm | ||

| Thickness | SJ/T11236-2001 ASTM F386-11 | 2.0, 2.5, 3.0mm |

| Surface resistance | SJ/T11236-2001 EN 1081 | 10e4-10e6 ohm conductive |

| 10e6-10e9 ohm antistatic | ||

| Voltage | AATCC-134 SJ/T11236-2001 | 50 V and 100V |

| IVI<100V | ||

| Static Decay | GJB2605-1996 | ≤2sec |

| Federal Test Method 1018 Method 4046 | 0.01sec | |

| Abrasive resistance(1000r) | SJ/T11236-2001 | ≤0.020g/cm2 |

| ASTM D1044-13 | 2500 0.48 | |

| 5000 0.95 | ||

| Fire resistance | SJ/T11236-2001 ASTM E648:2009a | FV-0 Class 1 |

| Dimensional | ASTM F2199:2009 EN 434 | ≤0.25% |

| Slip resistance wet | DIN 51130 | R9 |

| Residual concavity | SJ/T11236-2001 | ≤0.15 |

| EN 433 | 0.03 | |

| Color fastness | ISO 105B 02 | ≤6 |

| Chemical resistance | EN ISO 26987:2012 | OK |

| Toxic Tesing | GB 18586-2001 EN 71-3 | OK |

| Tvoc After 28 days | ISO 16000-3 | 10μ g/m3 |

| Wheel pressure | EN 425 | no effect |